Challenges

- Inaccurate data impacts inventory costs and customer satisfaction

- Out-of-date medicine is loss for the business

- Inventory out-of-stock results in loss of revenue

- Lack of reliable analytics hampers production planning and supply chain management

- Ineffective resource allocation affects labor, raw materials, and production capacity.

- Misaligned sales and marketing efforts result from inaccurate demand forecasts.

Solutions

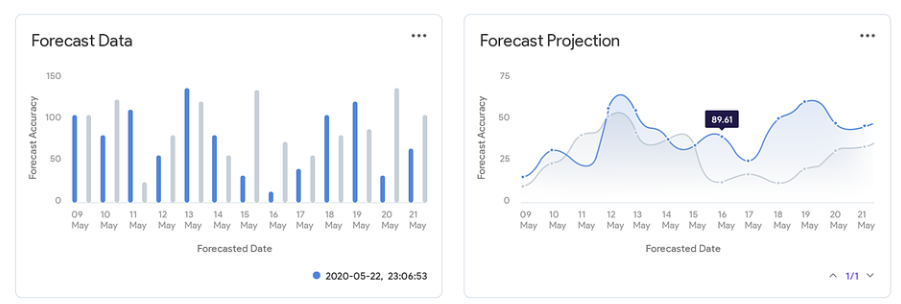

- Statistical methods like time-series analysis, moving averages, and exponential smoothing for accurate forecasts.

- Employ machine learning algorithms, such as neural networks, to capture complex demand relationships and enhance accuracy.

- Collaborate with stakeholders from sales, marketing, and supply chain for valuable insights.

- Continuously monitor and refine models to adapt to market dynamics, customer behavior, and external factors.

Benefits

- 30% deduction in out-of-stock items

- Improved Planning and Resource Allocation

- Increased Revenue and Profitability

- 20% reduction in out-of-date tablets

- Increased Flexibility

- Better Inventory Management

- Better Supply Chain Management

US based Health products company (ecommerce)

Within the context of demand forecasting for the customer, critical issues arise due to inaccurate data affecting inventory costs and customer satisfaction, leading to loss of revenue and inefficient resource allocation, necessitating the implementation of advanced statistical methods and machine learning algorithms to enhance accuracy and align sales, marketing, and supply chain efforts.